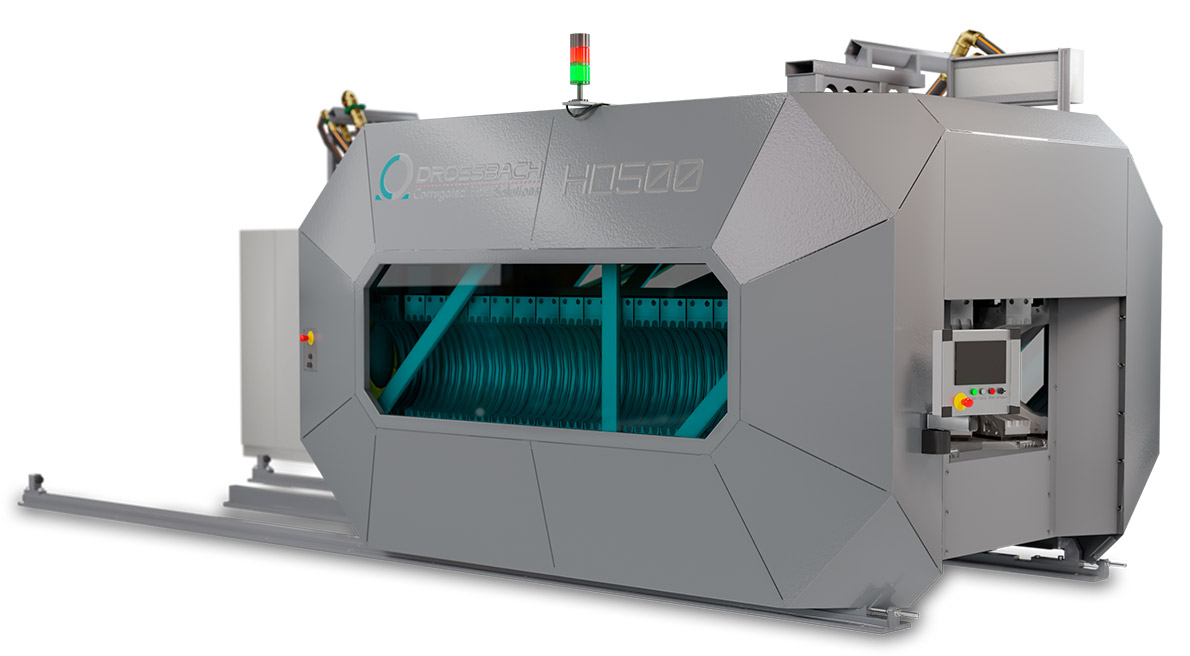

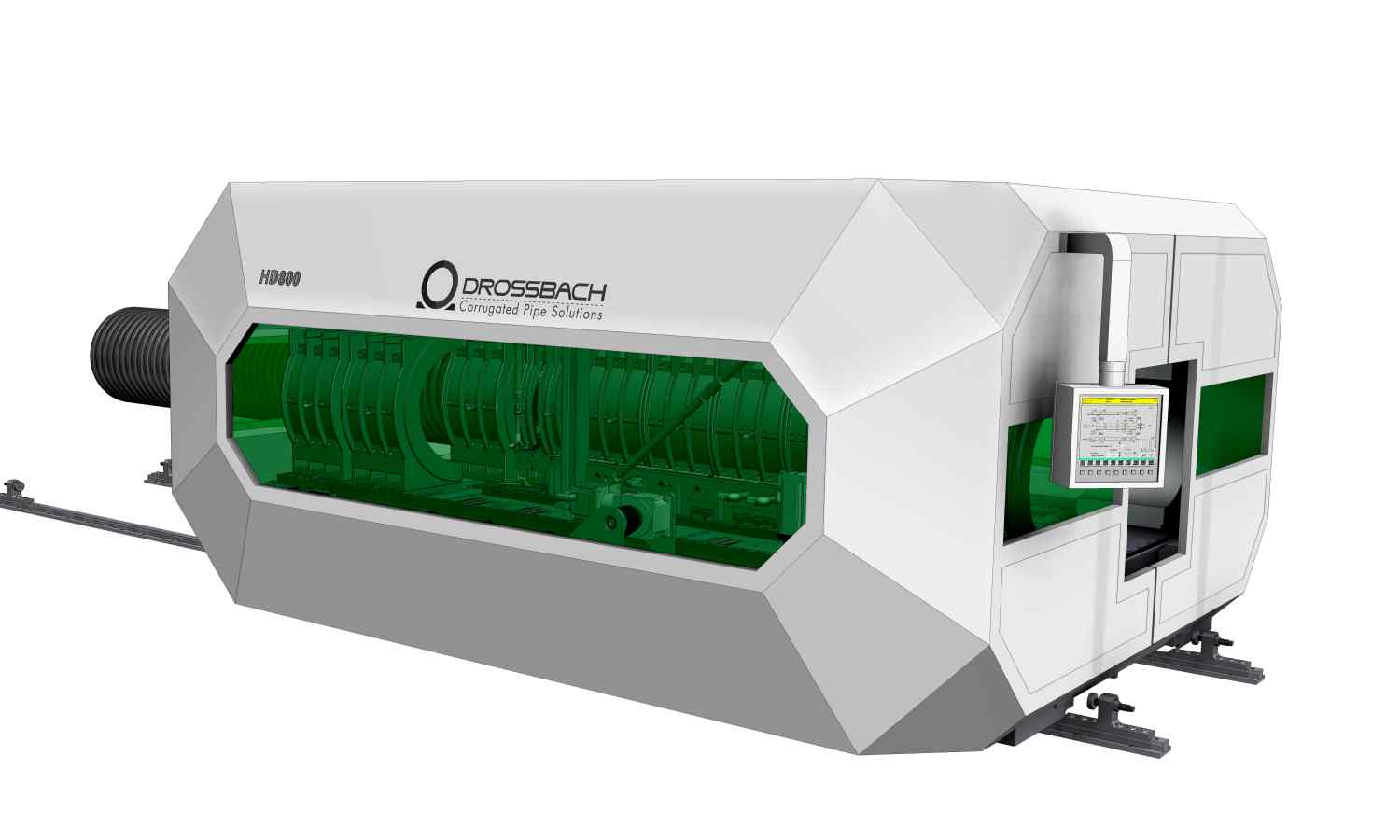

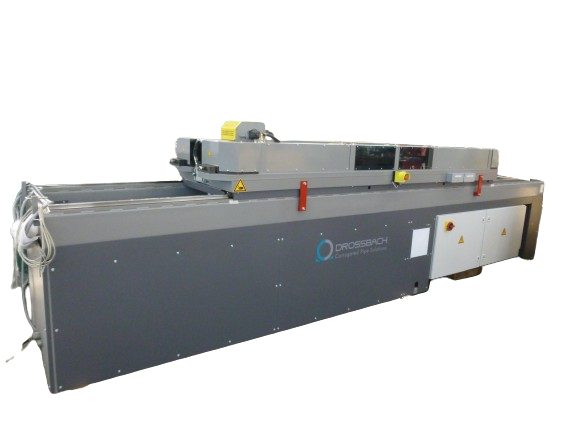

DROSSBACH HD 65-114

High speed corrugator for efficient production.

Technical Data

| Max. production speed | 40 m/min // 132 ft/min |

| PE/PP/PVC/PA output | 530 kg/h // 1168 lbs/h |

| Measurements / weight: | |

| - Max. pipe diameter (OD) | 65 mm // 2.½" |

| - Min. pipe diameter (ID) | 7 mm // 3/8" |

| Number of mold blocks (per side) | 114 |

| Length | 4694 mm // 14,3 ft |

| Width | 912 mm // 2,8 ft |

| Height (depending on extrusion height) | 1292 mm // 3,9 ft |

| Length of molding area | 2400 mm // 7,3 ft |

| Max.travel | 1650 mm // 5 ft |

| Weight of machine without mold blocks | 2100 kg // 4,630 lbs |

3d-Modell

3d-Modell

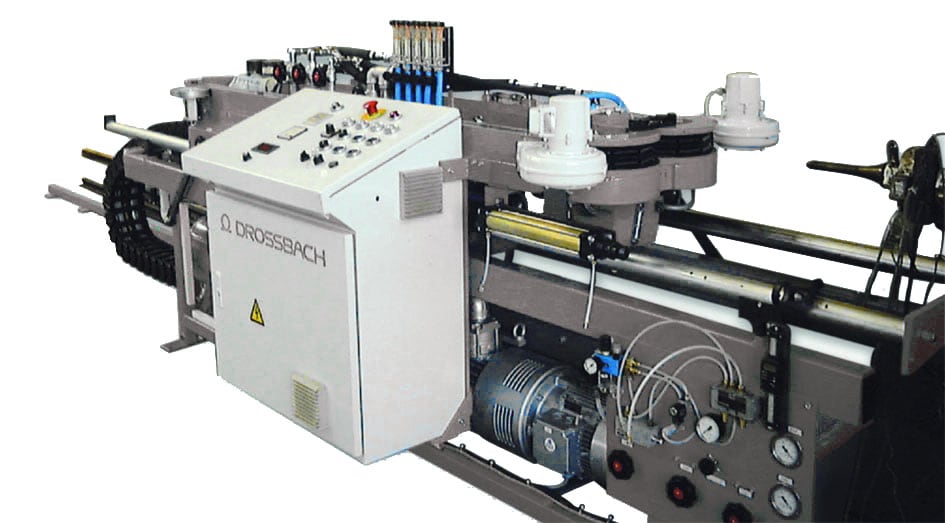

DROSSBACH HD 65-114 is a new generation of high-speed corrugators suitable for production of single- and double- wall corrugated pipes for wide range of applications (medical tubing, automotive, cable ducts, drainage, protection pipes, etc.).

-

High production speed due to 114 pairs mould-blocks with unique hybrid cooling system and integrated direct vacuum.

-

Corrugator is mounted onto a solid, welded frame which guarantees stability during high-speed production.

-

Electrically driven side adjustment with positional memory simplifies and speeds-up final tuning during production.

-

Automatic vacuum control for perfect profiling of corrugated pipes. For each diameter and material of pipe the necessary vacuum level is stored in PLC memory and selected on the operator’s panel.

-

Automatic cooling water temperature control.

-

Automatic heat-extension compensation of guiding curves for nonstop 24/7 highest speed production.

-

Easily accessible quick mold change system.

-

Maintenance-free operation thanks to fully automatic centralized lubrication system.

-

Maintenance-free frequency controlled built-in vacuum pump.

-

15” operator’ panel with intuitive easy-to-use interface.

-

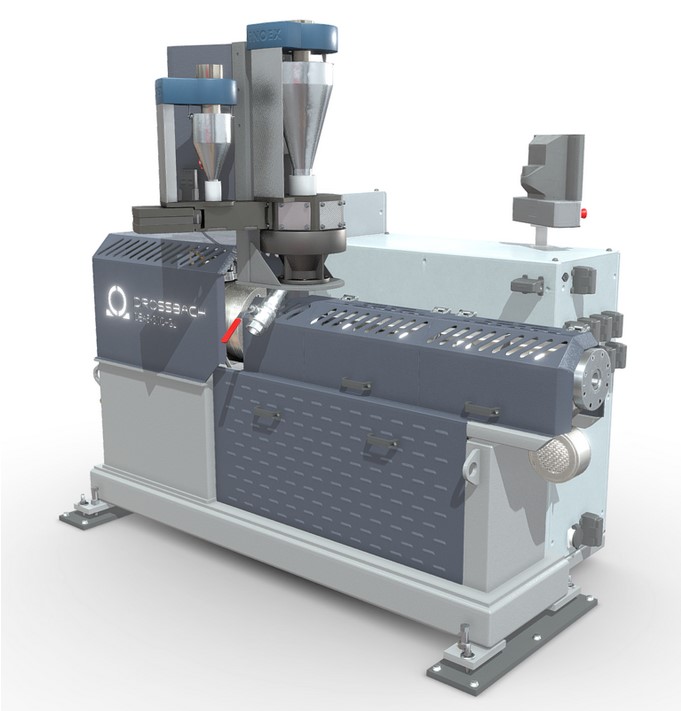

Full synchronization with extruders and downstream equipment via CanOpen, ProfiNet and analog.

-

Remote access via Internet for monitoring, diagnostics, and technical support.

-

In combination with DROSSBACH extruders the whole line can be monitored via one Internet connection.

DIAMETERS:

from ID7 mm to OD65 mm 3/8” / 2.½"

Materials:

PP, PE, PVC, PVDF, EVA, PA, PTFE (Teflon)